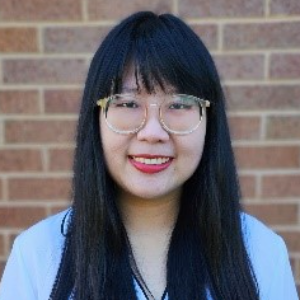

Raman Singh, Monash University-Clayton Campus, Australia

The talk will discuss the challenges in developing corrosion resistant graphene coating on most common engineering alloys, such as mild steel, and present recent results demonstrating circumvention of these challenges. In spite of traditional approaches of corrosion mitigation (e [....] » Read More

Scientific Programs coming soon..